POSITAL Position and Motion Sensors

A position sensor (also known as a motion sensor) is used to precisely determine the physical position and / or speed of the assembly attached to it at a specific and particular time. This information is then transmitted to a computer which will use it for system control or operations control purposes. The physical position can take several forms: it can be the location of the system in the environment, or its state with respect to an axis (rotation or inclination). The speed is obtained simply by deriving this position with respect to time.

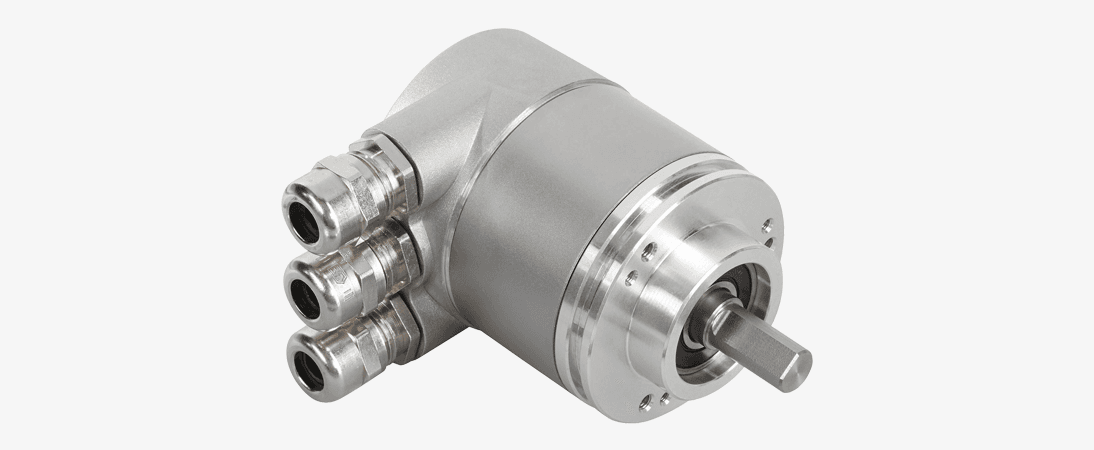

IXARC Absolute Industrial Encoders

Our absolute encoders deliver precision motion feedback solutions with standout features such as battery-free multiturn functionality, high-resolution performance, and robust high IP protection. What sets our encoders apart is their innovative technology and the large variety of mechanical and communication configurations for seamless integration. Our customers enjoy the benefits of our expertise and ability to provide tailor-made solutions for any application, from factory automation to hazardous environments, all at mass production prices.

IXARC Incremental Industrial Encoders

From material handling applications to harsh environments, our incremental encoders provide reliable speed and distance feedback while keeping the customers' system simple and cost-effective. With advanced programmability features, a large variety of mechanical configurations and high PPR, our encoders are designed for flexibility and ease of use. Our commitment to mass customization means we can deliver tailor-made solutions quickly, ensuring customers receive application-specific encoders at competitive prices.

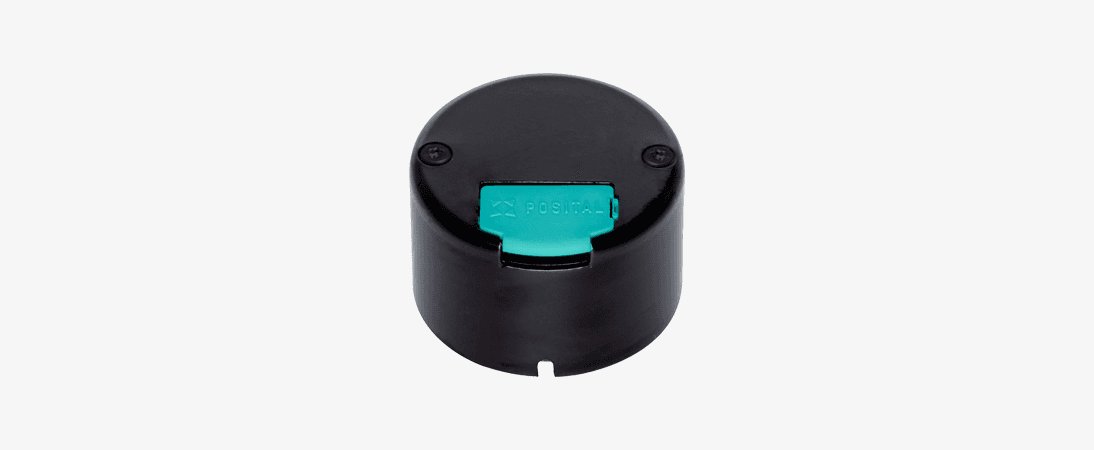

IXARC Kit Encoders

Our kit encoders offer smart motion feedback solutions for motors and robotics with unique benefits like battery-free multiturn functionality, excellent real-time performance, and compact design (down to 22mm). The modular design makes them also widely usable for a variety of applications in material handling and factory automation. What makes our sensors stand out is their innovative, gear free design based on Wiegand technology, easy installation and high resolution.

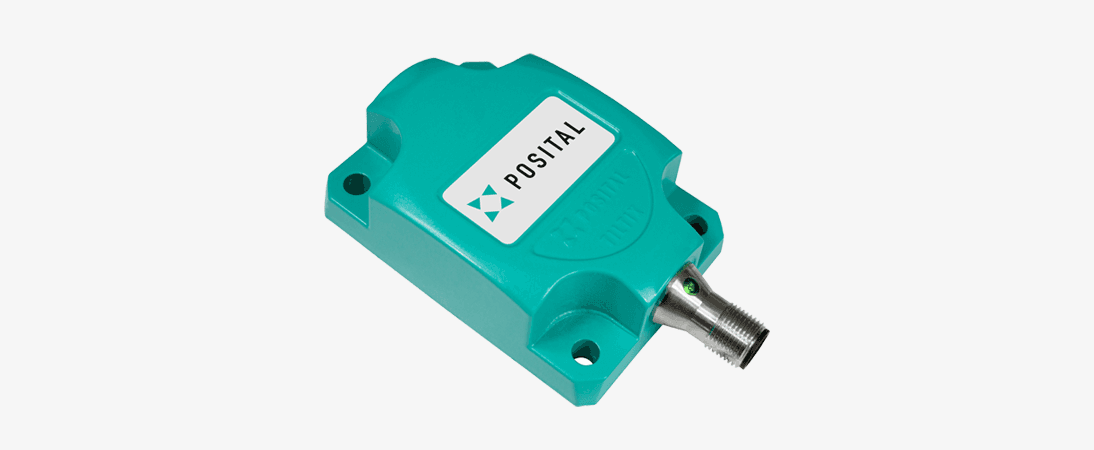

TILTIX Inclinometers

Our inclinometers offer a wide product portfolio, including static and dynamic models (IMU), ensuring easy integration, maintenance-free operation, and multi-axis measurements. We serve industries such as mobile machinery, mining, agriculture, and material handling with precise and robust tilt measurement solutions that enhance safety and efficiency. We stand out with precision, IP69K protection, and dynamic signal filtering, providing reliable performance in harsh environments with high shock and temperature variations.

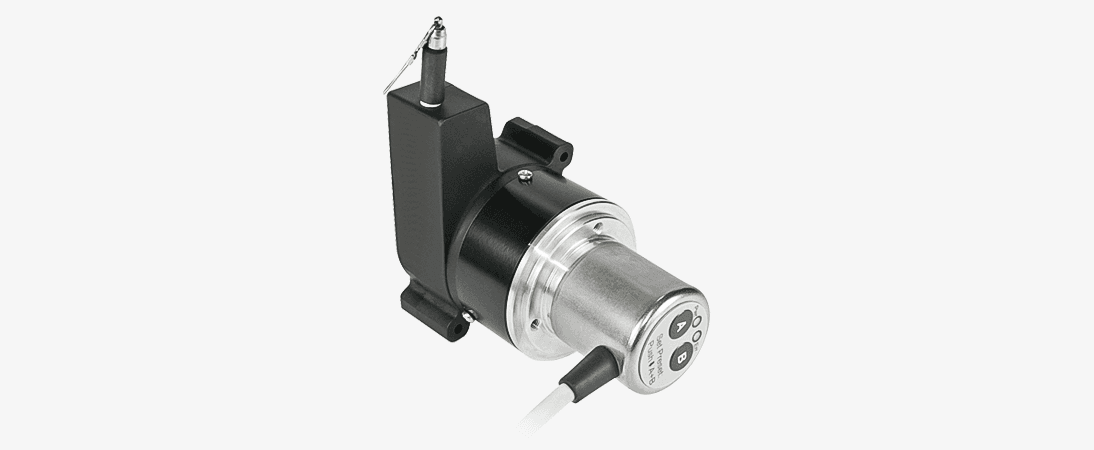

LINARIX Linear Sensors

Our linear sensors combine the precision motion feedback capabilities of our encoders with versatile draw wire or measuring wheel mechanisms, ensuring accurate distance measurement across any surface. Utilizing the advantages of high-resolution performance, and robust high IP protection, our sensors excel in diverse industrial applications. Customers benefit from our expertise in delivering tailor-made solutions at competitive prices, making our linear sensors the ideal choice for precise linear measurement solutions.

Sensors can be classified by using several different categories. The most commonly used are:

Categories | |

|---|---|

Accuracy | Corresponds to the smallest variation that the sensor can detect (degree, μm). |

Reliability | Corresponds to the average variation between two consecutive measurements. |

Resistance to Environmental Conditions | Typically temperature, humidity, dust and shock, corrosion, speed. |

Base Technology | Magnetic or optical, for example. |

Communication Interface | There are more than ten. |

Resolution | Is measured in bits. Generally between 8 and 16. This corresponds to the number of divisions for a unit of measure (e.g. 13 bits = 8,192 divisions for 360 °). |

Measuring Range | Measurement length or maximum angle of inclination. |

Mechanical Design | Different coupling options, flanges, etc. |

Connection | The output connection can be made with a cable or through connectors (male / female). |