ABSOLUTE SINGLETURN ANGULAR MEASUREMENT DEVICES

A Comparison of Inclinometers and Singleturn Rotary Encoders

Absolute angular measurement over a 360° range is notably one of the key measurements in many Industries and manufacturing units. In this article we will be discussing / comparing the similarities and the differences between single-turn rotary encoders and inclinometers based on their applications.

Encoders have evolved over time from simple incremental to more complex and very precise multiturn absolute encoders. The technology also has considerably changed. Various different technology options like optical, magnetic, and inductive are available with small differences in measurement resolution and accuracy. Whereas, inclinometers have been around for centuries and its evolution has been very diverse.

The basic principle of inclinometers is that it measures the tilt of a plane surface. The technology has slowly evolved from simple mechanics using air bubbles and pendulums, to modified potentiometers, to magnetic based measurement. At present, very advanced inclinometers like TILTIX from POSITAL use cutting edge MEMS technology for measurement.

A common misconception was that inclinometers cannot measure a full turn in the range of 0 − 359.99° like single turn encoders. But, the advances in technology have made that possible and only a few companies provide single axis inclinometers which can measure a full range of 360°. So, in this article we will compare our inclinometers and rotary encoders and discuss the possibility of inclinometers as replacements to single turn encoders in a few applications constrained by a few factors.

IXARC Magnetic Singleturn Encoders

The technology used to detect shaft position is fairly simple in magnetic encoders. There is a permanent magnet attached to the device’s shaft and a 2-axis Hall Effect sensor mounted on the encodercasing. As the shaft and magnet rotate the Hall Effect sensor measures changes in the magnetic field and reports the angular measurement to the control system. Because IXARC magnetic encoders are individually calibrated before they are shipped, they can also provide higher accuracy (around one part in a thousand) than that typical with other magnetic rotary encoders.

Click here for More Technical Information about Magnetic Encoders

IXARC Optical Singleturn Encoders

Optical encoders are made up of a revolving shaft with a code disc, an infrared light source and an optoelectronic scanning unit. The code disc is made of unbreakable plastics and usually printed with a unique pattern for each angular position (in Graycode). Infrared light from an LED is collimated and passed through the code disc. On the opposite side a photoreceptor array with a reticle picks up the information from the tracks. At every angle position a unique sequence of photoreceptors are blocked from light by dark segments on the code disc.

Click here for More Technical Information about Optical Encoders

TILTIX Highly Dynamic MEMS Inclinometers

It is basically a Micro-Electro-Mechanical Systems (MEMS) sensor cell containing an array of electrodes that is embedded to a fully molded ASIC. It works based on a simplified model with only two electrodes: one is fixed, and the other is flexible (connected with spring elements). When the inclinometer is in a horizontal position, a corresponding capacitance is measured. If the sensor is tilted, the flexible electrode will change its position relative to the fixed electrode. This results in a change of the capacitance between the two electrodes which is measured by the sensor cell. The change of the capacitance is converted to a corresponding inclination.

Click here for More Technical Information about Mems Inclinometer

Rotary Encoder and Inclinometer Compared

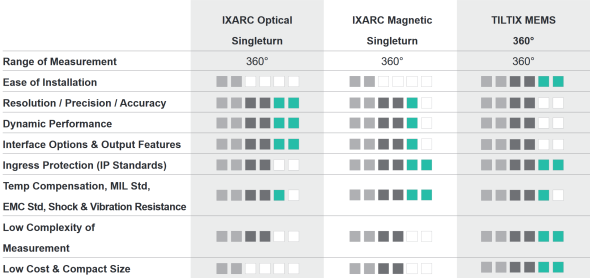

After a detailed research and survey we obtained an average of the parameter statistics primarily from Asia, Europe and the US for both encoders and inclinometers. These statistics were used as the reference for the following comparison of POSITAL’s line of single-turn encoders and inclinometers with each other and the other products in the same segment.

Easy of Installation

The installation compatibility of the sensor to the application is always an important consideration for users. The ease of installation also refers to the external mechanical accessories required and the mounting procedure before start up. The inclinometers can be setup on any surface with a simple 3/4 point raised mounting. This means that virtually, the inclinometer can be setup anywhere and everywhere for precise measurement. The encoder whereas needs a coupling and both the shafts have to be aligned to ensure the measurement axis is aligned. It requires a bit of expertise to set up a properly working encoder measurement mechanism. For example, in construction machines with long and large shafts- toothed belts, roller bearings and couplings need to be set up, to connect an encoder. Whereas, the TILTIX MEMS being pre-calibrated can be directly put into operation upon a simple mounting virtually anywhere on the moving part of the machine whose inclination has to be measured.

Low Cost and Compact Size

The cost and size are on everyone’s mind while choosing an absolute position sensing sensor. The encoders are generally priced high because their production is quite complex and has a number of internal components. In addition to that the encoders require additional mechanical components for installation which considerably increases their price. The encoders are generally fitted in line to the rotating shaft and unless we use a hollow shaft encoder this increases the system size. The TILTIX MEMS with the fully molded plastic housing is the most compact product among all the products compared and cheaper than most of them. However, it is interesting to note that IXARC magnetic encoders without its external components like couplings and toothed belts are comparable in price and size to TILTIX MEMS. They almost have the same volume and the only difference is that the inclinometer requires a simpler installation and occupies lesser space than magnetic encoders

Resolution, Precision and Accuracy

The encoders are by far the best options when resolution, precision and accuracy are concerned for a 360° range of measurement. Resolutions of up to 0.005° (16 bit) and accuracy of up to 0.01° is achievable due to the highly sophisticated optical discs and the expertise gained over the decades of IXARC encoder manufacturing at POSITAL.

The TILTIX MEMS inclinometer has relatively high resolution of 0.01° and accuracy of 0.1° but it is not as high as encoders. This is a major feature that is considered in applications that require precise movement and position analysis. The IXARC magnetic encoders have a good resolution of up to 0.005° (16 bit) and compared to other magnetic encoders has the very good accuracy of up to ±0.088°. This combination of resolution and accuracy makes these encoders one of the preferred choices in the magnetic encoder industry.

Dynamic Performance

The dynamic performance of a sensor is an important aspect in fast pace and very sensitive measurements. Basically, the encoders perform better dynamically since they can detect and measure the position at very high speeds of revolution. Moreover, they are less sensitive to vibrations compared to the other products and can measure even when subjected to very high vibration with a relatively good response time.

The TILTIX MEMS on the other hand has a very good response time but its dynamic performance is limited due to physical damping of frequencies above 29Hz. Although TILTIX MEMS is more sensitive to vibrations compared to encoders it has a good shock and vibration resistance. Hence, the TILTIX MEMS can measure with the same characteristics even after being exposed to a high shock and vibration, but preferably not during exposure.

Interface Options and Output Features

The availability of multiple interface options for an industrial product always provides an additional flexibility to its scope of application.

Different interfaces have different speeds and modes of operation and are designed for specific applications. Diverse communication options enhance the compatibility of the product as they offer a wide range of industrial used interfaces. Therefore, it is easier to add the encoders or inclinometers to the already available network or control interface.

IXARC optical encoders have the highest number of interfaces which include Bit-parallel, CANopen, DeviceNet, Profibus, Profinet IO + Ethernet/IP, Modbus, EtherCAT, Powerlink and Interbus communication.TILTIX MEMS inclinometer was initially confined to a few industrial segments but its recent advances into the factory automation sector is surely going to increase the demand for other electrical interfaces excluding the already available analog, CANopen, SSI and DeviceNet interfaces.

With increase in demand and with more users wanting to test the potential of TILTIX MEMS, interface development is imminent.In this context, the output features refer to the varied outputs configured in the device by processing of the measured position value.

The IXARC magnetic and optical encoders can give the position, speed, velocity, acceleration, alarms and warnings. Whereas the inclinometer can only give out the position value. Although it is possible to add such functions to the TILTIX MEMS it does not make sense to add time varying features like acceleration due to constraints in its dynamic performance. Flexibility of the output parameters are enhanced by the availability of boot loaders in IXARC optical encoders and TILTIX MEMS inclinometers. TILTIX MEMS can be configured using a simple RS232 interface and additionally, analogue teach-in (for Pre-set, Range and Filter length) is soon to be available for TILTIX MEMS and already available in IXARC magnetic analog encoders.

Dynamic Performance

IP standards define the protection of the device’s enclosure against external contaminants. The IP standards mentioned are attainable only with the appropriate accessories like connectors, couplings etc. There are waterproof IXARC magnetic, heavy duty encoders available for submergible applications and with a higher IP.

The inclinometers are comparatively a better choice to encoders when the application requires ruggedness and high environmental protection at a lower price. This is because it is easier to achieve high protection with inclinometers. In fact, the TILTIX MEMS inclinometers with a fully molded housing can attain protection levels of up to IP69K when used with just a proper counter connector. In the case of encoders, high IP protection of up to IP69K is attainable but will increase the costs. This is because of the increase in number of components and additional accessories which have to be appropriately chosen.

Temperature Compensation, EMC Standards, Shock and Vibration Resistance

POSITAL always emphasizes on protection, precision and steady measurements. Hence, both the inclinometers and encoders are equally matched in this aspect. Both have an emitted interference standard of EN 61000-6-4 and noise immunity standard of EN 61000-6-2.

IXARC optical encoders and TILTIX MEMS inclinometers can withstand shocks up to 200g and vibrations up to 20 g whereas IXARC magnetic heavy duty encoders can withstand up to 300g shock and 30g vibration. In IXARC optical encoders the plastic code disc is not going to change its dimension and in IXARC magnetic encoders the magnetic fields are quite resistant to variation in temperature. Therefore as far as applications in high temperature are concerned it is preferred to use encoders although the standards are equal. And in terms of shock and vibration resistance, both encoders and inclinometers can withstand high exposure but inclinometers cannot measure under the influence. This is because although the inclinometers are more robust every vibration means an acceleration, which will inflict the measurement result. Therefore an encoder mounted properly will not be affected by vibrations even during measurement

Complexity of Measurement

Complexity of measurement is a mixture of technology, processing of output and associated flexibility of measurements.

IXARC optical encoders, although very complex have been perfected with experience over 50 years of development and support. As seen in the technology it requires careful handling of the optical coded discs, the photoreceptor arrays and any contamination can affect the measurement. These are the physical limitations of IXARC optical encoders whereas in terms of software it is very flexible. There are even boot loaders available which enable more flexibility. Moreover, the IXARC optical line has almost all industrial interfaces available making it compatible to almost all the systems involving angular measurement.

IXARC magnetic encoders on the other hand have a very simple technology and very few mechanical parts. Hence, comparatively this requires very little maintenance and in terms of software maintenance, boot loaders with external interfaces are being developed and are soon to be released.

By far TILTIX MEMS is the least complex of measurements. It uses the MEMS technology and has an array of capacitive electrodes for highly precise measurement. The fully molded TILTIX MEMS is fully protected from external contaminants and gives it almost an infinite lifetime. High integration of components in a small and compact packaging like TILTIX MEMS makes it easier for the users. In terms of flexibility the TILTIX MEMS is completely configurable with the help of boot loaders, RS232 interface and also analog teach-in. Another main feature is the processing of output. Inclinometer outputs are simpler to decipher because they are not coded. Generally, analog inclinometers and encoders give directly proportional outputs to every corresponding position whereas other inclinometers with field busses directly give out the position value. But in the case of encoders (except for the analog ones) a general rule is that the encoders gives out a coded position value which need to be finally deciphered through a minor calculation executed by the user in a PC or respective control systems. Hence the processing is comparatively complex in case of encoders.

Range of Measurement

The initial comparison is with respect to the measurement rangs of POSITAL’s products. An important feature to be considered in TILTIX MEMS inclinometers is the ability of it to be mounted almost anywhere. This added flexibility is an advantage when compared to other inclinometers available in the market and as an alternative solution to single turn encoders in a few applications.

Industries

TILTIX MEMS inclinometers, for instance is the best choice for applications and industries which require a good range of resolution/accuracy over a 360° range but with space and installation constraints. Unarguably, the most attractive feature of TILTIX MEMS is its compact size, its ability to be mounted vertically or horizontally and easy installation almost anywhere. Cost-wise TILTIX MEMS is the best option and it can be very useful in many industries like construction, robotics, and mining and in various applications involving farm machinery, mobileplatforms, solar energy and drilling machinery where TILTIX MEMS’s compact size, high ingress protection and simple measurement and output features will be an added advantage.

The IXARC optical encoders on the other hand have a very high resolution/accuracy, best dynamical performance, good resistance to temperature, shock and vibration and diverse output features. The most important aspect of IXARC encoders is the availability of all the communication interfaces in the industry which makes it easy to install in already available networks. These characteristics find applications in elevators, control systems, defense equipment, industrial robots, medical equipment, manufacturing, automotive where multiple outputs have to be monitored and the precision, resolution are all important considerations. Summarizing, the IXARC optical encoders are best needed when there is a need for high end dynamic sensing & measurement and there are no constraints on cost, size and skilled labor.

The IXARC magnetic encoders are very much similar to the optical encoders in the fields of application and characteristics. Major differences arise only with respect to the technology of measurement, the cost and size. Heavy duty magnetic encoders are available which are smaller in size when compared to optical but have high protection of up to IP69K and are even submergible (but with a lesser IP). All these characteristics lead to the use of magnetic encoders in industries which require good resolution, compact size, low cost and varied output features like industrial doors, drives and gear motors, food product machinery, material handling, rolling mills, wind energy, port machinery and textile industries.

Conclusion

For detecting up to 360°, POSITAL provides various options as discussed earlier and the user never needs to worry about the compatibility of the output to the equipment because as mentioned earlier, all the products come with a variety of communication interfaces to facilitate diverse fields of application. The single axis inclinometers and the singleturn encoders are two devices which measure in a range of 360°, but are chosen according to the characteristics of the measurement undertaken and its compatibility. When it comes to multi-turn, the encoders are the only option available. But in case of singleturn there is always an option of using inclinometers as replacements to the encoders.